We have industrialized a natural process.

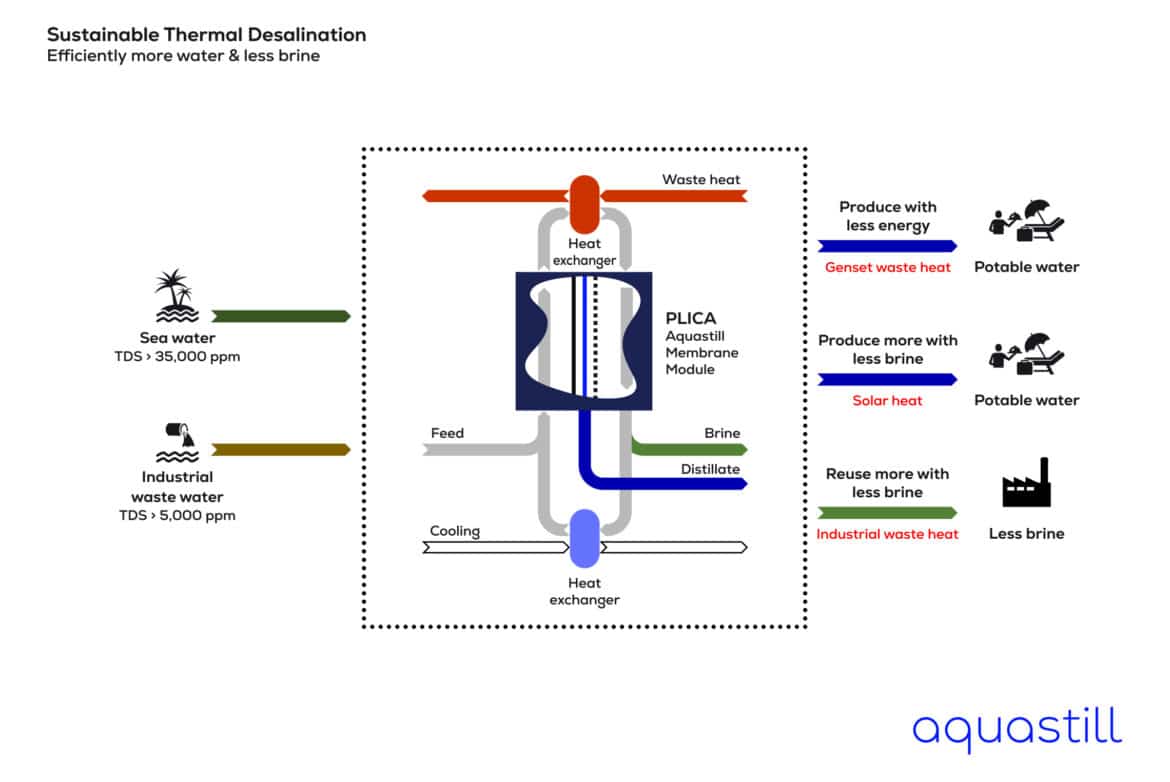

At Aquastill we have industrialized a natural process and made membrane distillation (MD) applicable. On a medium scale (1000 m3/day), but on a smaller scale (10 m3/day) as well. In contrast to other thermal technologies, membrane distillation can be highly efficient on a smaller to medium scale, making it a very interesting solution when large scale implementation is not desirable nor possible.

Applicable and complementary.

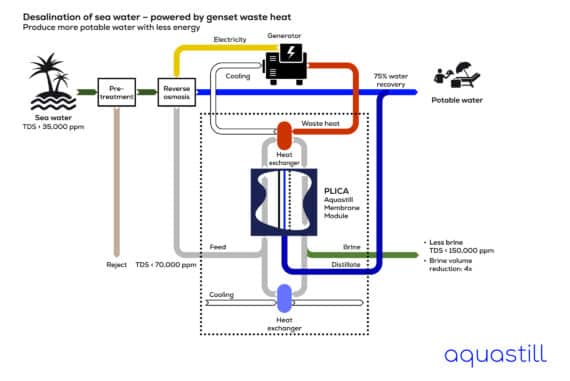

Aquastill has made membrane distillation applicable and scalable, but complementary as well. As a hybrid system with other membrane water treatment systems such as reverse osmosis (RO), ultrafiltration (UF), nanofiltration (NF), microfiltration (MF) and forward osmosis (FO). It is also with renewable energy technologies like solar, photovoltaic, salt gradient solar and geothermal systems. So if you want to use renewable heat and regenerate saline water, you go to Aquastill.

Aquastill’s technology can operate at a very wide range of salinity, making MD suitable to treat feeds that vary from pure seawater to several forms of industrial waste water, while achieving the main needs of our customers. Either your goal is to greatly increase the volume of clean water produced without comparably raising your energy costs (to get the maximum clean water yield of your feed with very small amount of brine to discharge) or to make greater use of your waste water by reusing most of it, Aquastill is ready to help with these challenges.

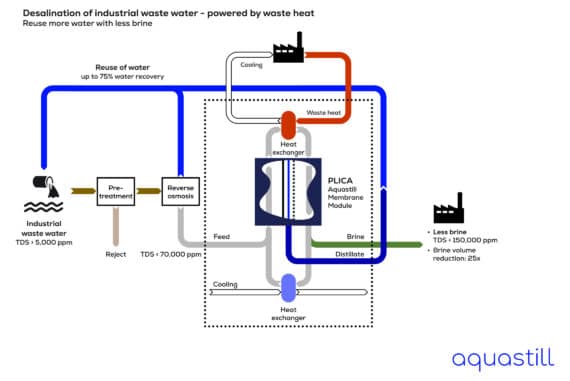

Desalination of industrial waste water powered by waste heat.

Reuse more water with less brine

In industry in general, fresh water is a fundamental resource for innumerous applications. For example: the oil and gas industry, which uses a great portion of its fresh water intake to inject into the reservoir to counteract the subsoil pressure and achieve high recovery levels…

Membrane distillation

for off-grid toilet concepts.

Membrane distillation re-invented

Our modular membrane distillation (MD) technology offers a suitable water purification method as part of a special project to shape the future of sanitation. We have developed a compact version of our…

Contact